In today’s fast-paced market, packaging is no longer just a functional necessity; it’s a strategic tool that impacts branding, efficiency, and profitability. The right packaging machinery can significantly influence product quality, shelf appeal, and operational costs, making it a crucial investment for businesses looking to stay competitive and future-ready.

Whether you’re a startup navigating initial growth challenges or a large-scale enterprise optimizing existing processes, selecting the appropriate packaging machinery can be a game-changer. This blog explores how investing in advanced packaging solutions can maximize efficiency, enhance product appeal, and drive long-term profitability.

Why Packaging Machinery is Essential for Business Growth

The packaging industry is evolving rapidly, driven by rising consumer expectations for sustainable, visually appealing, and durable packaging. To meet these demands, businesses need packaging solutions that ensure:

- Efficiency: Automated machinery accelerates production processes, reducing downtime and improving output.

- Consistency: Precise and uniform packaging enhances brand credibility and customer satisfaction.

- Cost Savings: By reducing manual labor, material wastage, and operational inefficiencies, businesses can improve profit margins.

- Compliance: Meeting regulatory standards for food safety, pharmaceuticals, and other industries with certified packaging machinery.

Investing in high-quality packaging machinery isn’t just about operational convenience; it’s about securing a competitive edge and building a brand that resonates with customers.

Key Considerations When Choosing Packaging Machinery

To make an informed investment in packaging machinery, businesses must consider the following critical factors:

Product Requirements

Understanding your product’s characteristics is crucial to selecting the right machinery. Ask yourself:

- Is your product liquid, solid, or powder-based?

- What packaging type best suits your product—bottles, pouches, cartons, shrink wraps?

- Are there any special requirements like airtight sealing, tamper-evidence, or UV protection?

For instance, products like beverages or oils require high-precision filling machines to prevent leaks and ensure accurate volume. Fragile products like glass bottles may need cushioning features for safe handling.

Scalability & Future Expansion

Your packaging needs today might not be the same tomorrow. Choosing machinery that allows for modular upgrades and scalability ensures long-term cost-effectiveness. Look for solutions that can adapt to:

- Increased production capacity.

- New product launches or packaging types.

- Changing consumer preferences and regulatory standards.

Automation Level

The degree of automation directly affects labor costs and efficiency. Depending on your business size and production goals, you can choose from:

- Manual Packaging Machines: Suitable for small-scale operations with limited budget and output requirements.

- Semi-Automatic Machines: A cost-effective choice for businesses transitioning from manual to automated processes.

- Fully Automatic Systems: Best suited for high-volume operations requiring precision, speed, and minimal human intervention.

Cost vs. ROI

While investing in premium packaging machinery may have a higher upfront cost, the long-term benefits in terms of reduced operational expenses, enhanced productivity, and improved product quality often outweigh the initial investment.

How Packaging Machinery Impacts Profitability

The right packaging machinery can directly contribute to increased profitability by:

- Boosting Productivity: Machines optimize speed and accuracy, ensuring quicker turnaround times to meet market demand.

- Minimizing Errors: Automated processes reduce human errors, ensuring consistent packaging quality.

- Reducing Material Waste: Precision machinery uses packaging materials more efficiently, leading to cost savings and sustainability benefits.

- Enhancing Brand Value: High-quality, well-packaged products create a premium perception, increasing customer trust and loyalty.

By streamlining production processes and reducing inefficiencies, businesses can increase their output and maximize their bottom line.

Emerging Trends in Packaging Machinery for 2025

The packaging industry is experiencing significant technological advancements, with a focus on sustainability, efficiency, and innovation. Some of the key trends shaping the future of packaging machinery include:

- Smart Packaging Automation:

IoT-enabled machinery with sensors and real-time monitoring capabilities help businesses optimize performance, reduce downtime, and ensure predictive maintenance. - Sustainable Packaging Solutions:

With increased demand for eco-friendly packaging, businesses are investing in machinery compatible with biodegradable materials, recyclable packaging, and energy-efficient operations. - Flexible Packaging Solutions:

Machines that can handle various packaging formats—such as resealable pouches, flexible films, and rigid containers—allow brands to cater to diverse consumer preferences. - AI-Driven Quality Control:

Advanced machinery now integrates AI-powered inspection systems to detect defects, ensuring consistent quality and reducing product recalls.

By adopting these trends, businesses can stay ahead of competitors while meeting evolving consumer and regulatory demands.

Types of Packaging Machinery and Their Applications

Different types of packaging machinery cater to various business needs. Understanding the options available can help businesses choose the right solution:

Filling Machines

- Ideal for: Liquids, pastes, powders, and granules.

- Benefits: Ensures precise volume control and reduces spillage.

Capping Machines

- Ideal for: Bottles and jars across industries like cosmetics, pharmaceuticals, and beverages.

- Benefits: Provides airtight sealing to maintain product freshness and prevent leaks.

Labeling Machines

- Ideal for: All types of packaged products that require branding and regulatory labeling.

- Benefits: Ensures consistent and professional label placement, enhancing product appeal.

Shrink Wrapping Machines

- Ideal for: Multipack consumer goods and fragile items.

- Benefits: Provides tamper-proof and visually appealing packaging.

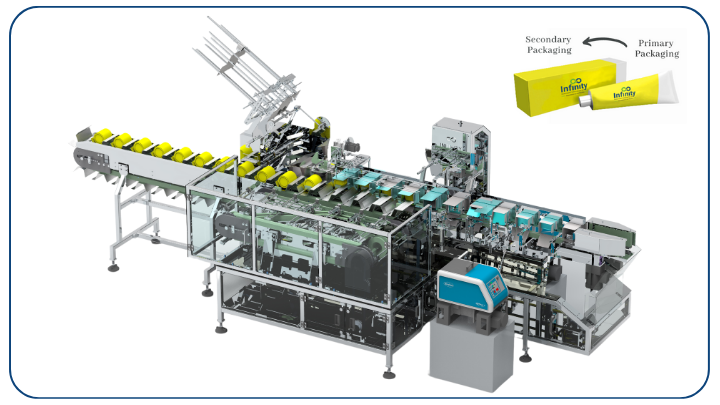

Cartoning Machines

- Ideal for: Packaged foods, pharmaceuticals, and cosmetics.

- Benefits: Ensures safe transportation and attractive retail presentation.

Each of these machines offers unique benefits, enhancing packaging quality and efficiency for businesses across various sectors.

Why Choose Akikai Packaging Machines?

At Akikai Packaging Machines, we offer advanced, customizable packaging solutions tailored to meet your business needs. Whether you’re looking for precision, automation, or sustainability, our cutting-edge machines provide:

- High-Precision Filling and Sealing: For consistent and accurate packaging.

- Eco-Friendly Packaging Options: To align with sustainable business goals.

- Comprehensive Support: From consultation to after-sales service, ensuring seamless operations.

With our expertise, businesses can scale effortlessly, enhance efficiency, and maintain product integrity.

Final Thoughts: Is Your Business Ready for the Next Level?

Investing in the right packaging machinery isn’t just a necessity—it’s a strategic decision that defines your brand’s future. With the right solutions in place, businesses can:

- Increase productivity and efficiency.

- Reduce operational costs and material wastage.

- Enhance their market presence with superior packaging quality.

At Akikai Packaging Machines, we are committed to helping businesses find the perfect packaging solutions that align with their goals. Whether you’re looking to automate, scale, or enhance your packaging, we’re here to help.

Need some amazing and eye-catching Packaging Solutions for your products?

Contact our packaging advisors today to learn more about our products and services, and to address any question/query.

Connect with us:

Email at sales@ajantabottle.com

Phone/Whatsapp: +91 9891098918

You can also shop from more than 500+ packaging solutions on www.ajantabottle.com – India’s first ever comprehensive packaging e-commerce portal.

For additional information, browse through our blog at https://www.ajantabottle.com/blog/ or subscribe to our latest updates through our social media channels,

*YouTube channel: https://www.youtube.com/c/Ajantabottle

*LinkedIn Page: https://www.linkedin.com/company/ajantabottle

*Facebook Page: https://www.facebook.com/glassbottleindia

*Instagram Page: https://www.instagram.com/ajantabottle/

*Google Business Profile Manager: https://g.page/r/CXTH9MKpe2DuEBM/review