The packaging industry is undergoing a rapid transformation, driven by increasing demands for sustainability, efficiency, and consumer safety. As global awareness of environmental issues grows, businesses are seeking innovative solutions to reduce waste, improve product safety, and enhance the consumer experience. Enter nanotechnology—a groundbreaking innovation that is reshaping the packaging landscape by enhancing material properties at the molecular and atomic level.

Nanotechnology is already being integrated into various packaging materials, including glass, plastic, aluminum, and paperboard, each benefiting from advanced properties that improve durability, safety, and eco-friendliness. With continuous advancements, nanotechnology is proving to be an indispensable tool in modern packaging solutions.

In this blog, we will explore the current applications of nanotechnology, its real-world usage by major brands, the future of nano-enabled packaging, and the challenges associated with its adoption.

Current Applications of Nanotechnology in Packaging

Nanotechnology is already making significant strides in various packaging materials. Some of the key areas where nanotechnology is being utilized include:

1. Enhancing Barrier Properties

Nanoparticles are being integrated into packaging materials to develop ultra-thin yet highly effective protective barriers against moisture, oxygen, and UV light. These advanced barriers help extend shelf life, maintain product quality, and prevent contamination. This innovation is particularly crucial in packaging perishable goods such as pharmaceuticals and food items, where even minimal exposure to air, humidity, or light can degrade product integrity, alter composition, and reduce effectiveness.

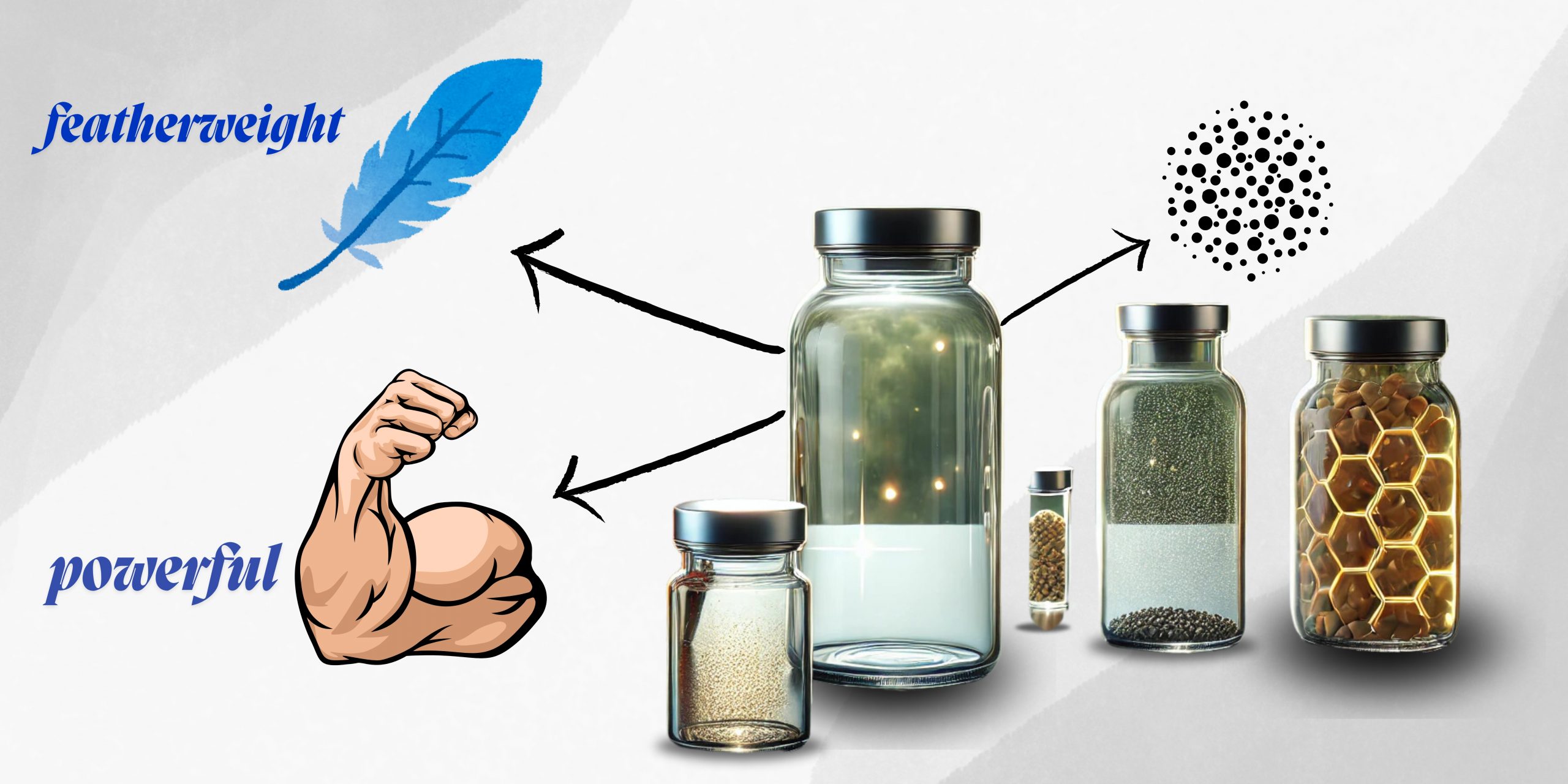

By enhancing durability and providing superior protection, nanotechnology is transforming the way sensitive products are preserved and delivered to consumers. Glass packaging already offers excellent barrier properties; however, incorporating nano-coatings can further enhance its capabilities by providing additional resistance to UV rays and enhancing scratch resistance, making glass jars and bottles even more durable and lightweight.

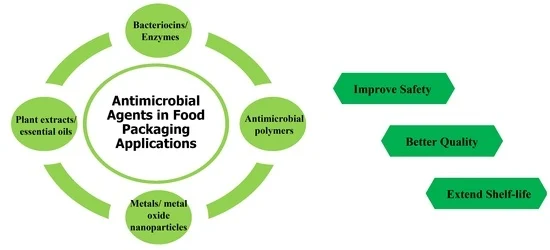

2. Antimicrobial Packaging for Extended Shelf Life

Incorporating antimicrobial nanomaterials into food packaging has garnered significant interest due to their potential to enhance food safety and extend shelf life. Nanoparticles such as silver and copper are known for their natural antibacterial properties, which can inhibit microbial growth on food surfaces. This approach aims to maintain product freshness and reduce spoilage.

However, recent studies have raised concerns regarding the migration of these nanoparticles into food products. For instance, research indicates that silver nanoparticles embedded in plastic packaging can leach into dry foods, leading to potential health implications. Consequently, the use of silver nanoparticle-infused packaging is not currently approved in the United States or Europe.

Glass, by nature, is a non-reactive material, but introducing antimicrobial nano-coatings can further enhance its capabilities for applications such as honey jars, spice bottles, and pharmaceutical vials, ensuring the contents remain uncontaminated for longer periods.

3. Intelligent Packaging with Smart Sensors

Nanotechnology is significantly advancing the field of smart packaging by enabling real-time monitoring of product conditions through the integration of nanosensors. These nanosensors can detect environmental changes such as temperature, humidity, and spoilage indicators, providing immediate feedback to ensure product quality and safety.

Food Industry Applications:

In the food sector, smart packaging equipped with nanosensors can monitor factors like temperature and humidity, which are critical for perishable goods. For instance, nanosensors can detect spoilage signs and alert consumers, thereby preventing foodborne illnesses and reducing waste.

Pharmaceutical Industry Applications:

In pharmaceuticals, smart packaging solutions can prevent drug degradation by monitoring environmental conditions. For example, temperature-sensitive packaging can maintain drug viability, with reports showing effectiveness levels remaining above 90% throughout shipping. These advancements in smart packaging, facilitated by nanotechnology, are transforming how industries monitor and maintain product integrity, leading to enhanced safety and quality assurance for consumers.

4. Lightweight and High-Strength Packaging

Nanotechnology is significantly advancing the development of lightweight yet high-strength packaging materials, offering numerous benefits across various industries.

Lightweight and High-Strength Packaging Materials:

Incorporating nanomaterials, such as carbon nanotubes and nanoclays, into packaging polymers enhances mechanical properties, allowing for reduced material usage without compromising strength. This approach leads to lighter packaging solutions that maintain durability and integrity during transportation and storage.

Real-World Applications of Nanotechnology in Packaging

Several major packaging companies and brands have successfully integrated nanotechnology into their packaging processes to improve quality, enhance sustainability, and optimize costs. Some notable examples include:

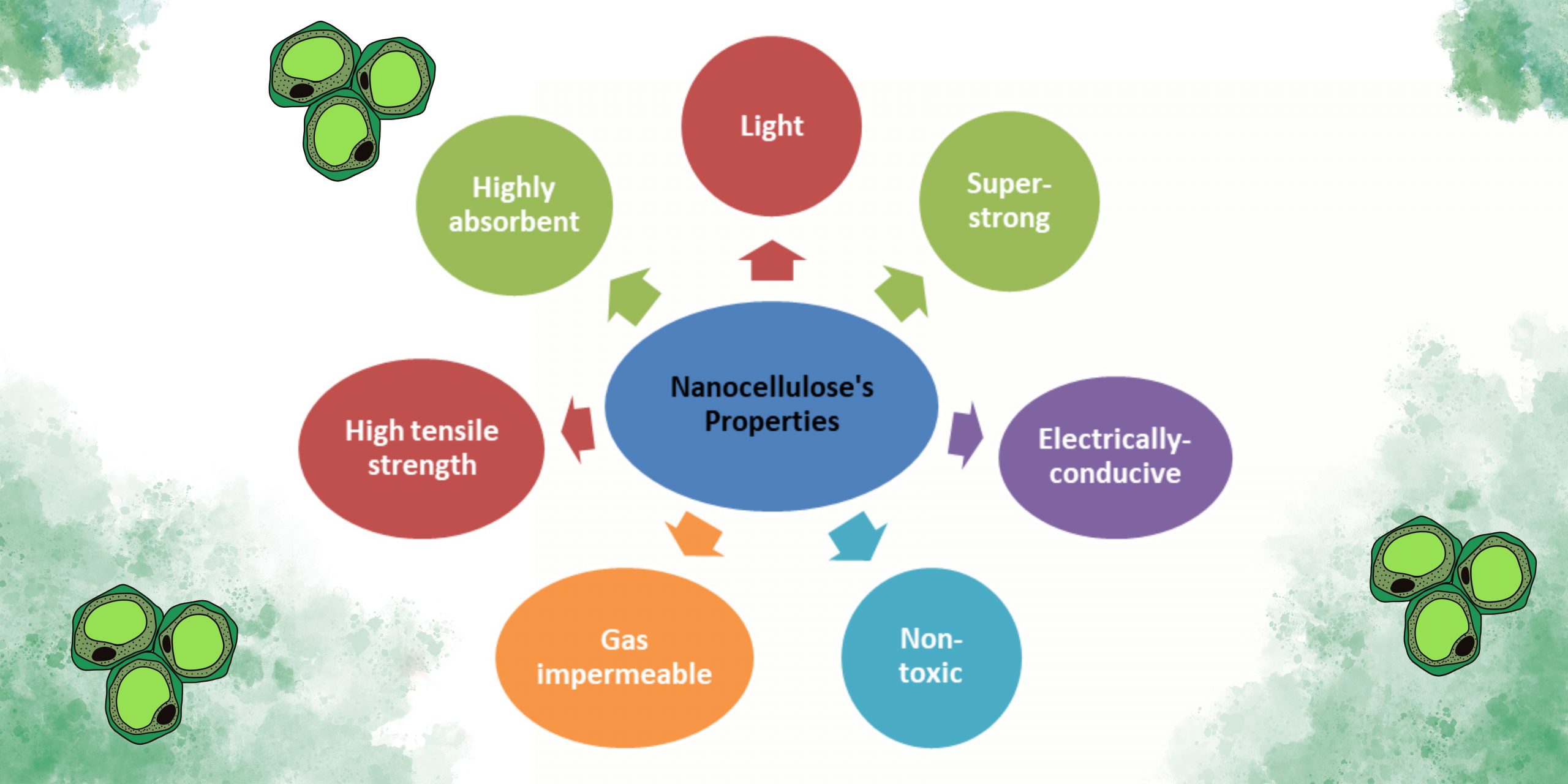

- Nanocellulose, derived from natural sources, has been utilized to stabilize Pickering emulsions, which are emulsions stabilized by solid particles. These emulsions have potential applications in food packaging, offering improved barrier properties and stability. Research indicates that nanocellulose can effectively stabilize these emulsions, leading to innovative packaging solutions.

- Amcor, a global leader in responsible packaging solutions, has entered into a joint research project with Nfinite Nanotechnology Inc. to validate the use of Nfinite’s nanocoating technology. This collaboration aims to enhance both recyclable and compostable packaging by applying nanocoatings to improve oxygen barrier performance. The initial phase involves integrating Nfinite’s coating technology with Amcor’s existing packaging materials, with future plans to explore bio-based substrates for increased sustainability.

- LifeSpan has developed a copper-based film that leverages nanotechnology to create safer and more sustainable packaging solutions. This innovative approach addresses the growing demand for eco-friendly products by utilizing the antimicrobial properties of copper at the nanoscale.

Future Prospects of Nanotechnology in Packaging

Nanotechnology is poised to revolutionize the packaging industry, offering innovative solutions that enhance sustainability, intelligence, and functionality. Future advancements are expected to focus on several key areas:

1. Sustainable and Eco-Friendly Packaging

Nanotechnology enables the development of biodegradable and compostable materials that match the performance of traditional packaging. For instance, nano-cellulose films derived from renewable sources like wood pulp are being researched for their strength and biodegradability.

These films not only provide robust packaging solutions but also contribute to environmental sustainability by reducing reliance on non-degradable polymers.

2. Customizable Smart Packaging

Brands are leveraging nanotechnology to create personalized packaging experiences. Smart packaging equipped with nanosensors can monitor internal environments, providing data on factors such as spoilage and shelf life.

This real-time information enhances consumer engagement and ensures product quality. Additionally, integrating features like embedded QR codes and augmented reality applications can offer interactive experiences, further personalizing the consumer journey.

3. Edible and Dissolvable Packaging

Innovations in edible packaging involve applying nano-coatings directly to food, eliminating the need for traditional materials. Dissolvable films infused with nutrients or vitamins are also under development, providing functional and sustainable alternatives.

These advancements not only reduce packaging waste but also offer added health benefits to consumers. As research progresses, nanotechnology is expected to play a pivotal role in transforming packaging into more sustainable, intelligent, and functional solutions, aligning with evolving consumer demands and environmental considerations.

Challenges in Implementing Nanotechnology in Packaging

Implementing nanotechnology in packaging offers numerous advantages, but several challenges hinder its widespread adoption:

Regulatory Concerns: The potential migration of nanomaterials into food products has raised safety concerns. Regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) are conducting extensive studies to assess the safety of nanomaterials in food packaging applications.

The lack of comprehensive regulations and standardized safety protocols contributes to uncertainty among manufacturers and consumers.

Production Costs: Integrating nanotechnology into packaging materials often requires specialized manufacturing processes and equipment, leading to higher production costs. These expenses can be prohibitive, especially for small and medium-sized enterprises (SMEs), limiting their ability to adopt nanotechnology in their packaging solutions.

Consumer Perception: Public skepticism regarding the safety of nanomaterials poses a significant barrier. Educating consumers about the benefits and safety of nanotechnology in packaging is crucial to overcoming this skepticism. Transparent communication and public engagement are essential to build trust and facilitate acceptance.

Addressing these challenges requires collaborative efforts among researchers, industry stakeholders, regulatory agencies, and consumer advocacy groups to develop safe, cost-effective, and publicly accepted nanotechnology applications in packaging.

Nanotechnology in Different Packaging Materials

Nanotechnology is revolutionizing packaging across various materials, each benefiting uniquely from its application:

- Enhanced Durability: Applying nano-coatings to glass surfaces improves their strength and scratch resistance, extending the lifespan of glass containers.

- UV Protection: Nano-coatings can also provide UV protection, safeguarding light-sensitive products from degradation.

- Smart Features: Integration of nanotechnology enables the development of smart glass bottles with interactive elements, enhancing consumer engagement.

Plastic Packaging:

- Improved Barrier Properties: Incorporating nanomaterials into plastics enhances their barrier properties against gases and moisture, thereby extending product shelf life.

- Antimicrobial Effects: Embedding nanoparticles with antimicrobial properties into plastic packaging helps inhibit bacterial growth, maintaining product freshness.

- Sustainability: Nanotechnology allows for the production of lighter and more durable plastic packaging, reducing material usage and environmental impact.

- Corrosion Resistance: Applying nano-coatings to aluminum surfaces enhances their resistance to corrosion, thereby extending the shelf life of canned beverages and foods.

- Smart Indicators: Nanotechnology enables the creation of smart aluminum cans equipped with temperature indicators, providing consumers with information about the optimal consumption conditions.

- Energy Efficiency: Nano-structured surfaces can improve the recyclability of aluminum and reduce energy consumption during production, contributing to more sustainable packaging solutions.

These advancements demonstrate how nanotechnology is tailoring packaging solutions to meet specific material needs, enhancing performance, and adding value across the packaging industry.

Conclusion: A Bright Future Ahead

As the packaging industry continues to evolve, nanotechnology stands at the forefront of innovation, driving advancements in sustainability, product safety, and consumer engagement. From enhanced barrier properties and antimicrobial coatings to smart packaging solutions and lightweight materials, nano-enabled packaging is transforming how products are protected, preserved, and presented.

While challenges such as regulatory approvals, production costs, and consumer perception remain, ongoing research and industry collaboration are paving the way for safer and more efficient nanotechnology applications. As businesses adapt to evolving consumer demands and environmental responsibilities, embracing nanotechnology will no longer be an option—it will be a necessity.

With continuous breakthroughs on the horizon, the future of packaging is smarter, safer, and more sustainable than ever before—and nanotechnology is leading the way.

Need some amazing and eye-catching Packaging Solutions for your products?

Contact our packaging advisors today to learn more about our products and services, and to address any question/query.

Connect with us:

Email at sales@ajantabottle.com

Phone/Whatsapp: +91 9891098918

You can also shop from more than 500+ packaging solutions on www.ajantabottle.com – India’s first ever comprehensive packaging e-commerce portal.

For additional information, browse through our blog at https://www.ajantabottle.com/blog/ or subscribe to our latest updates through our social media channels,

*YouTube channel: https://www.youtube.com/c/Ajantabottle

*LinkedIn Page: https://www.linkedin.com/company/ajantabottle

*Facebook Page: https://www.facebook.com/glassbottleindia

*Instagram Page: https://www.instagram.com/ajantabottle/

*Google Business Profile Manager: https://g.page/r/CXTH9MKpe2DuEBM/review