Have you ever wondered how Glass bottles and Glass jar manufacturing takes place?

In today’s blog you will get answers to all your questions related to manufacturing of glass bottles and jars.

Mainly, glass container production in modern factories pass through three stages:

- The Batch House stage – deals with handling of the raw materials.

- The Hot End stage handles the manufacturing and moulding process — the forehearth, forming machines, and annealing ovens.

- The Cold End stage– deals with product-inspection and packaging equipment.

Let’s read about these three stages in detail.

Batch House Stage of Manufacturing of Glass Bottles

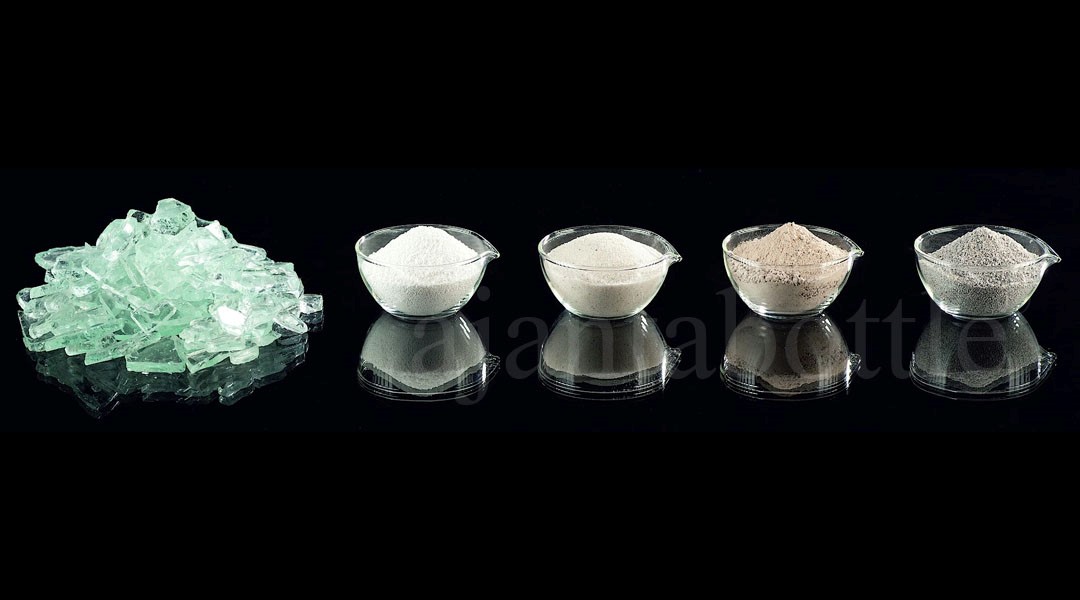

Stage 1: Collection of Raw Material

Natural raw materials are used for manufacturing of glass bottles and glass jars for packaging. These raw materials are Silica and Soda lime. These materials perform different functions like, soda is used for lowering the melting point of sand and lime helps in making the glass hard, shiny and durable. Cullet is broken glass which is obtained from the bottles rejected by manufacturers of glass bottles, from the recycling points, bottle banks or kerbside collection system. It is very beneficial in manufacturing of glass containers.

Stage 2: Preparation of Batch

The batch is prepared on a grinding machine. Raw material, cullet (shredded glass pieces) and decolourisers / colourisers are ground finely in a grinder. The next step is to properly weigh these ingredients in the correct proportions before mixing them together. The mixing of these ingredients is usually done in a mixer until a homogeneous mixture known as a batch or frit is obtained. Before being fed to the kiln, the batches are stored in large vertical silos. The batch is now taken for further process of melting in a furnace.

Hot End stage of Manufacturing of Glass Bottles

Stage 3: Melting in Furnace

The mixture continues to melt in a furnace heated to a temperature of about 1748 °C. The furnace operates 24 hours a day, 7 days a week and has a service life of approximately 1012 years. The raw material entering the furnace turns into glass containers in about a day. Molten glass is delivered to the forming machine through a series of distribution channels called forehearths. At the end of the forehearths, the flow of glass is cut into pieces that are tightly controlled by weight, shape and temperature.

Stage 4: Forming at Present

Manufacturing of glass bottles is done by two methods: B&B (Blow and Blow) process and NNPB (Narrow Neck Press and Blow) process. Both processes involve cutting a stream of molten glass with a cutting blade at a temperature of about 1,050–1,200 °C to form a rigid glass cylinder commonly referred to as a gob.

Please note that the gob is of predetermined weight, which is sufficient for manufacturing of glass bottle. Both B&B and NNPB processes start with the falling of gob, by gravity, and are guided through chutes, into the blank moulds, Two halves of moulds are clamped shut and then sealed by the baffle from above. However, in the B&B process, the parison is blown while in the latter, pressing forms the glass container parison.

If you want another blog on these two processes, comment below or let us know through the links mentioned further below.

Stage 5: Annealing

To ensure the strength of a newly formed glass vessel, it must be heat treated and subjected to controlled and uniform cooling in a tunnel kiln known as an “annealing lehr”. This can take anywhere from 30 minutes to 2 hours. If the cooling is uneven, the load will weaken the glass. An annealing oven commonly known in the industry as a lehr heats the vessel to about 580°C and then cools it down for 20-60 minutes, depending on the thickness of the glass.

The Lehr is a moving conveyor with different temperature zones. To make glass bottles and glass jars more scratch-resistant, they are usually treated with a hot applied top coat before entering the lehr and an additional coating as it cools as it leaves the lehr. This completes the glass container manufacturing process.

- Cold End stage of Manufacturing of Glass Bottles

Stage 6: Coatings

Usually there are two surface coatings done on glass bottles and glass jars. The first one is done before annealing, at the hot end and the other one happens at the cold end, right after annealing.

A thin layer of tin oxide is applied to the hot end using a safe organic compound or inorganic stannic chloride. The tin-based systems are not the only solution, but they are the most widely used. Besides these, titanium tetrachloride or organo titanate can also be used. However, in all cases the coating makes the glass surface better adhere to the cold end coating. On the cold end, a layer of polyethylene wax is usually applied via an aqueous emulsion.

They are also coated to prevent the containers from sticking together as they move along the conveyor. In other words, the coating gives the glass a virtually scratch-resistant surface. It is basically made of special glass. As a result of reducing surface damage during use, coatings are often described as hardening and less commonly as retaining strength coatings.

Stage 7: Quality Inspection Machines

Glass containers are 100% checked for the presence of various defects, both automatically and manually.

The defects of glass containers can be of various different kinds. The glass can have small cracks called checks, and sometimes foreign objects called stones can penetrate the walls of the glass container.

Other defects include air bubbles (i.e. bubbles in the glass) and unnecessarily thin walls. Another common defect in glass container manufacturing is called a tear. In the press and blow method, if the plunger and the mould are misaligned or if they are not heated to the correct temperature, the glass will stick to the object and break.

In addition to rejecting defective containers, the inspection equipment also collects and transmits statistical information from the hot end to the operator of the forming machine. Computer systems collect misinformation and track down the mould the glass container was made from. This is possible by reading the mould number of the container coded on the container by the mould that made it. Any containers that do not meet the standards are automatically rejected and returned to the furnace for remelting.

Stage 8: Secondary Processing

Glass container manufacturers also offer additional services such as labelling. Although several marking options are available, the unique technology for glass is the Applied Ceramic Marking (ACL) process. At the same time, screen-printed decorations are applied to the container with glass enamel paint and then baked. Coca-Cola’s original bottle is a well-known example of this.

Stage 9: Packaging

Glass containers are packaged differently. Bulk pallets, for example, are very popular in Europe, which can hold between 1,000 and 4,000 containers each. Automatic machines (eg palletizers, line and stack containers separated by sheet layers). Other options include boxes and hand-sewn bags. Once packed, new “in-stock items” are tagged, stored in a warehouse, and finally shipped. Glass jar manufacturers in India use shrink and carton boxes are the most used for glass jar and glass bottle packaging.

If you are looking for Glass Jars and Glass Bottles online, please visit: https://ajantabottle.com/

For more blogs and videos on glass packaging material, visit https://www.ajantabottle.com/blog/

For the latest updates on glass packaging, subscribe to our

*YouTube channel: https://www.youtube.com/c/Ajantabottle

*LinkedIn Page: https://www.linkedin.com/company/ajantabottle

*Facebook Page: https://www.facebook.com/glassbottleindia/

*Instagram Page: https://www.instagram.com/ajantabottle/

To know more about glass jars and bottles, refer to India’s only and first ever book on glass packaging, “Through The Glass – Past. Present. Only future” authored by our director, Mr. Deepanker Agarwal. The Amazon link to purchase the book is:

https://www.amazon.in/dp/9390757991/ref=cm_sw_r_sms_api_i_3K9513241EK3HMP4PAA8